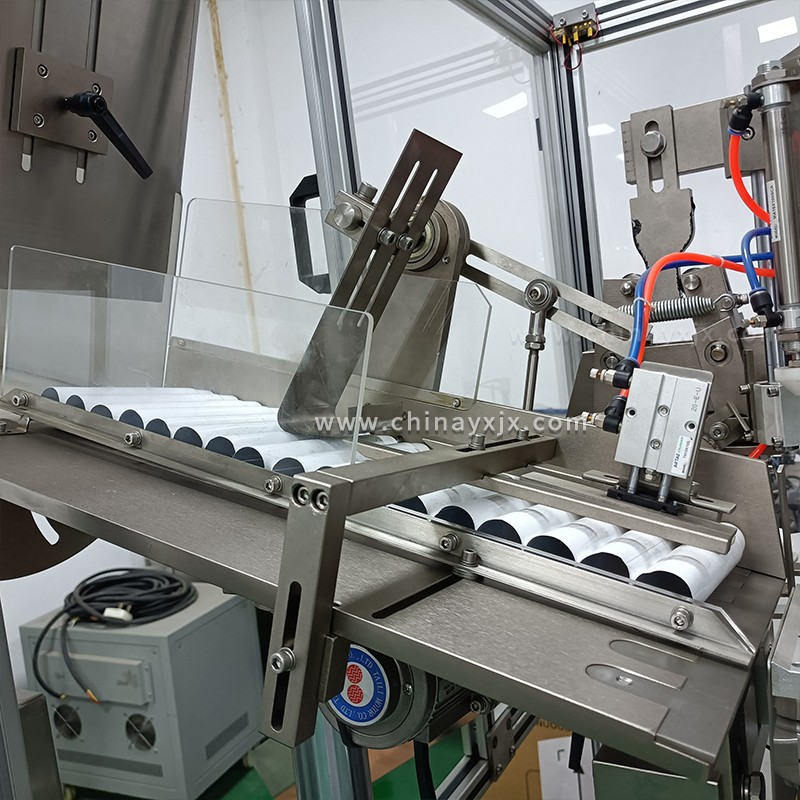

Auto tube filling and sealing machines are commonly used in the cosmetic and toothpaste industry for efficient packaging. These machines automate the process of filling cosmetic creams and toothpaste into tubes and sealing them for a secure and professional finish. They offer several features and capabilities, including:

Tube positioning: The machine positions the tubes correctly to ensure accurate filling and sealing.

Filling mechanism: It employs a precise filling mechanism to fill the tubes with the desired amount of cosmetic cream or toothpaste. This can be adjusted according to the specific product requirements.

Sealing method: The machine utilizes various sealing methods such as heat sealing or ultrasonic sealing to ensure a tight and leak-proof seal on the tubes.

Automatic operation: These machines are designed for automated operation, reducing the need for manual intervention and increasing production efficiency.

Speed and capacity: They are capable of high-speed filling and sealing, enabling large-scale production. The capacity varies depending on the specific machine model.

Versatility: Auto tube filling and sealing machines can handle different tube sizes and materials, accommodating a range of cosmetic creams and toothpaste products.

Quality control: They often incorporate quality control systems to detect and reject faulty tubes, ensuring only properly filled and sealed tubes are packaged.

Overall, auto tube filling and sealing machines provide reliable and efficient packaging solutions for cosmetic creams and toothpaste, streamlining the manufacturing process while maintaining product integrity and hygiene standards.